Everything, everything, I mean, EVERYTHING we use and have comes from the earth. That’s the clothes we wear, the homes we live in, the food we eat, the vehicles we use, the phones we talk on, etc., etc., etc. Did you ever think about how glass is made? What about the soda can you might drink out of? Where does that come from? And that little plastic tab that comes on your bread so it can stay fresh? It’s crazy to think all of that came from the earth. At Sustainable Schools we often focus on how to reduce waste by recycling or reusing but the first “R” of Reduce, Reuse and Recycle (we like to say there are many more Rs) is first for a reason.

When we know the work and materials that go into making a product, the idea of using something only once doesn’t seem to make sense – and therefore reducing our consumption of that product helps to save our natural resources! In this series, we will explore how things are made from our natural resources and how its production affects our environment. We will explore how materials like paper, aluminum, glass and plastic are made and why it’s important to reuse and recycle them.

This week we are going to focus on aluminum!

So, how is Aluminum made?

Creating aluminum is a very chemistry heavy process! Especially when brand new aluminum is produced, and is NOT made with recycled materials. For simplicity sake, these are the four steps:

1. An ore called Bauxite needs to be extracted from the earth’s crust. That means a hole needs to be blown out of the ground so the material can be scooped out.

2. The bauxite is transported to a facility where it needs to be refined to remove unwanted compounds. The white powdery material that is left is called alumina.

3. Through chemicals and high heat, the alumina is turned into a molten liquid.

4. Lastly, the molten liquid is shaped into sheets and formed into cans that are filled with beverages!

Aluminum can also be made using aluminum that has been recycled! Refer to the chart below to see how the two processes differ.

Making aluminum with recycled materials cuts out steps 1 and 2, and instead, the recycled aluminum is shredded and heated up to a molten liquid. It can then be shaped into sheets and formed into cans once again! Watch this video to learn more about the process of turning recycled aluminum cans into new cans! Making cans out of recycled material means there is no extracting, no separating, and no refining! This is much less impactful on humans and the environment. Let’s take a deeper look.

The Human Impacts

Bauxite is usually extracted from tropical forests where many indigenous tribes, or tribes that have been living there since before aluminum was discovered, live. In order to get to the site and transport the bauxite, networks of mining roads and railways crisscross rural communities that were once isolated. Can you imagine all the noise that comes with a road being built? You would probably hear a lot of loud heavy machinery and trucks moving around, and trees being bulldozed. This is the sounds you would be hearing instead of the sounds of wildlife around you and the trees blowing in the wind like you would normally have heard.

In one community in the Boké region, in northwestern Guinea (which is in Africa), the industrial ports where the bauxite is brought, is very close to wetlands, paddy fields (which are usually flooded parcels of land that are used for growing semi aquatic crops), and fishing ports that the communities rely heavily on. Damage to water sources like contamination from the extraction process, as well as increased population migration to mining sites, is reducing the communities’ access to clean water for drinking, washing and cooking. In some villages, people have to get their water from nearby streams and wells. (They don’t have pipes that bring the water to their homes like we do here.) But, with some of these streams and wells becoming contaminated, some people are now forced to walk longer distances or wait for longer periods of time to obtain clean water from alternative sources.

In addition, the dust produced from mining the bauxite and transporting it smothers fields and enters homes, leaving families and health workers worried that reduced air quality threatens their health and environment.

The Environmental Impacts

There are many impacts to the environment that come with making aluminum brand new, and not from recycled materials. Throughout the process, roads are required to transport material back and forth, and a lot of fuel is used in the transportation of material as well as the machinery that is used in the facilities.

![]()

The creation of roads and the use of fuel has its own array of environmental impacts, but here are some other environmental impacts to think about:

The Extraction of Bauxite

In order to get to the bauxite, wide swaths of habitats are destroyed, as is the ability for the forest to moderate local weather patterns, moisture, and carbon dioxide levels. The destruction of the forest also reduces wildlife food and habitats, thus reducing biodiversity. Also, since the earth is now bare, water runs over it more easily and carries mud into the rivers with each rainstorm, contaminating local waterways.

![]()

Refining of Bauxite to Produce Aluminum

Not only are many machines used in the process of refining bauxite, but a lot of chemicals are used as well. With the use of so much machinery, a lot of fuel is required, most often fossil fuels that produce greenhouse gases when they are burned.

![]()

In addition, through the process, a red mud is produced. This mud can contain toxic metals and chemicals, and can not be easily reused. Every ton (2,000 pounds) of aluminum cans that are made produces about 5 tons (10,000 pounds) of red mud. The red mud is hard to store, so it must be put into a lagoon to contain it, which ends up contaminating both surface water and groundwater.

![]()

Lastly, a lot of freshwater is used in the process for producing steam, washing ore, vehicle washing, sanitization, etc. Freshwater is precious as it is a limited resource on Earth!

So, why recycle?

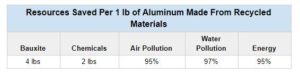

Recycling your aluminum has many benefits. Aluminum can be used over and over again without losing its value! Did you notice all the icons next to the photos above? Those are some of the major resources that are required in creating aluminum from raw materials (not recycled). That is a lot of fuel, water, trees, and biodiversity that can be saved if we create new aluminum from recycled aluminum! The table below shows a little more detail about how much resources are saved when we recycle our aluminum.

In Whatcom County, we are lucky that our aluminum items can be picked up and recycled. After the items leave our curb, they will be delivered to Alabama, where they are smelted into aluminum sheets to make new aluminum cans! So you can recycle all your aluminum knowing they will be back on the shelves within 60 days!

So, what can you do?

Don’t wish-cycle (hope an item you have is recyclable)! Just because something is shiny and silver it does not mean it is made of metal and can be recycled. Let’s take the inside of your chip bag. It looks like aluminum foil but it’s most likely just plastic, like most food wrappers, and this plastic cannot be recycled – as plastic or metal!

A good way to know whether or not it is made only with aluminum and thus can be recycled, you can do this scrunch test!

Before tossing your aluminum foil in the recycling bin – make certain it’s clean. If it has baked on cheese, or meat juice or pie crust you should throw it out! But if items are clean, they can be recycled as well!

Besides containers holding food items, you can also recycle almost anything made with aluminum; tent poles, lawn chairs made with aluminum, etc., though they may not be eligible for curbside pick up – check with your hauler.

Lastly, don’t throw anything made of metal, aluminum or steel, into the landfill. If they end up in the landfill they can’t be recycled. It will take 200-500 years before they finally decompose, taking up valuable space!

So please always recycle your clean aluminum!

Take Action

Another thing you can do that will reduce the amount of aluminum used and made, is re-use the aluminum that you have! For example, you can do an upcycling project with your cans.

Some ideas include:

1. Upcycle an aluminum can into garden art!

2. Fill up your clean can with dirt and planting herbs in them. You can even punch holes in the bottom for drainage!

3. Decorate the outside of the can and cut off the top. Now it’s a holder for paint brushes, pencils, push pins, rubber bands, whatever!

We would love to see what you do.

Please share with us how you decide to reuse your aluminum cans! Take a picture or video and send them to us or tag us on Instagram (@resources_protects)!

Continue learning

There are lots of topics for you to choose from. Don’t stop here; move on to discover another lesson! New lessons uploaded each week.